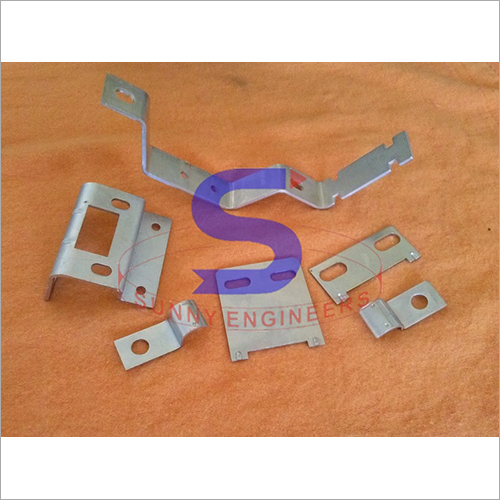

Automotive Brackets

Price 5 INR/ Piece

Automotive Brackets Specification

- Mount Type

- Bolt-On

- Surface Finishing

- Matte Black Finish

- Hole Size

- 12 mm

- Coating Type

- Anti-Corrosion Powder Coating

- Dimension (L*W*H)

- 120mm x 80mm x 40mm

- Shape

- L-Shaped

- Usage

- Mounting & Support

- Components

- Bracket Body, Mounting Holes

- Weight

- 350 g

- Application

- Automotive Assemblies

- Material

- Mild Steel (MS)

- Tolerance

- 0.05 mm

- Thickness

- 3 mm

- Capacity

- Heavy Duty - up to 150 kg

- Surface Treatment

- Powder Coated

- Making Process

- Stamped & Pressed

Automotive Brackets Trade Information

- Minimum Order Quantity

- 500 Pieces

- Supply Ability

- 300000 Pieces Per Month

- Delivery Time

- 30 Days

About Automotive Brackets

Proceeding in the making qualitative items for a huge trap of associations reliably at a huge scope. At a similar point, we are making acceptable quality Bracket Component which is normally made of metal however it can likewise be made of wood or plastic. The metallic edge sections highlight gaps in them for screws. Its average use is to join a wooden rack to a divider or to consolidate two furniture parts. We deliver this Bracket Component within a stipulated time frame.

Specification

Thickness | 1 to 3 mm |

Usage/Application | Garage |

Material | Mild Steel |

Brand | Sunny |

Surface Finish | Polished |

Tolerance | 0.02 mm - 0.04 mm |

Exceptional Corrosion and Temperature Resistance

Engineered to withstand extreme conditions, these powder-coated brackets are corrosion-resistant and maintain performance in temperatures from -40C to +120C. The durable finish safeguards against environmental effects, ensuring long-lasting reliability for automotive assemblies.

Precision Manufacturing for Heavy-Duty Use

Produced through advanced stamping and pressing, each bracket ensures dimensional accuracy with a tolerance of 0.05 mm. Its mild steel construction and robust design enable a load capacity of up to 150 kg, making it ideal for demanding mounting and support applications.

FAQs of Automotive Brackets:

Q: How are the automotive brackets installed on vehicles?

A: Installation is straightforward using the four 12 mm mounting holes provided, with a bolt-on mount type for easy attachment to passenger cars and light trucks. The deburred smooth edges ensure a safe and secure fit during assembly.Q: What is the significance of the brackets anti-corrosion powder coating?

A: The anti-corrosion powder coating offers advanced protection against rust and moisture, enhancing the brackets longevity even in harsh environmental conditions. This makes them suitable for various automotive applications prone to exposure.Q: When should these brackets be used within automotive assemblies?

A: These brackets are ideal for mounting and support requirements in automotive assemblies where robust strength and reliability are essential, particularly in areas exposed to vibration or intense mechanical stress.Q: Where are these brackets manufactured and exported from?

A: Manufactured in India by an experienced supplier and exporter, the brackets are distributed worldwide to meet the requirements of automotive manufacturers and service centers, ensuring quality and compliance with ISO 9001:2015 standards.Q: What process ensures the brackets dimensional accuracy and high load capacity?

A: Each bracket is stamped and pressed from mild steel, allowing for tight tolerances of 0.05 mm. This precision manufacturing guarantees consistent dimensions and a heavy-duty capacity supporting loads up to 150 kg.Q: What packaging options are available for these brackets?

A: The brackets can be shipped in either corrugated boxes or poly packs, offering secure and reliable packaging during transit and storage, tailored to custom bulk or retail requirements.Q: What are the benefits of choosing these automotive brackets for mounting needs?

A: By combining corrosion and temperature resistance, strict import standards compliance, and customization options, these brackets deliver durability, adaptability, and enhanced performance for automotive mounting and support applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sheet Metal Components Category

Customized Sheet Metal Brackets

Price 5 INR / Piece

Minimum Order Quantity : 500 Pieces

Surface Finishing : Smooth, Polished

Mount Type : Wall Mount, Panel Mount, Floor Mount

Making Process : Other, Laser Cutting, CNC Bending, Welding, Punching

Hole Size : Custom; Typically 3 mm 15 mm

Sheet Metal Brackets

Price 5 INR / Piece

Minimum Order Quantity : 500 Pieces

Surface Finishing : Smooth, anticorrosive coated

Mount Type : Screw Mount

Making Process : Other, Laser Cut and CNC Formed

Hole Size : 9 mm

Sheet Metal Pressed Component

Price 5 INR / Piece

Minimum Order Quantity : 500 Pieces

Surface Finishing : Smooth, Burr free, Corrosion resistant

Mount Type : BoltOn, WeldOn, Screw Mount

Making Process : Other, Stamping, Pressing, Forming

Hole Size : Customizable as per drawing

Automotive Metal Stamping

Price 5 INR / Piece

Minimum Order Quantity : 500 Pieces

Surface Finishing : Polished, Painted, Plated

Mount Type : BoltOn, WeldOn

Making Process : Other, Stamping, Punching, Deep Drawing, Bending, Forming

Hole Size : Custom as per requirement

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS