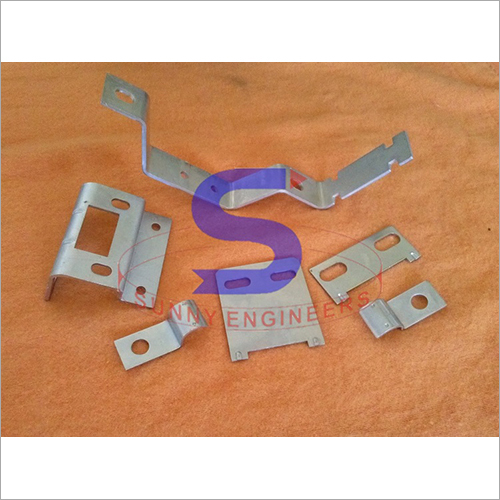

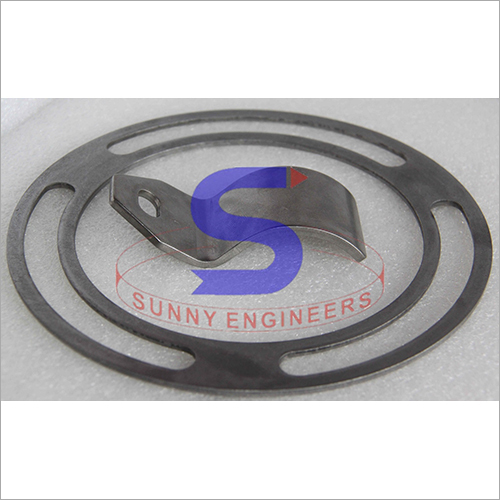

Customized Press Parts

Price 5 INR/ Piece

MOQ : 500 Pieces

Customized Press Parts Specification

- Load Capacity

- Up to 500 kg or customized

- Thickness

- 0.5 mm to 10 mm

- Hole Size

- 1 mm to 20 mm or customized

- Application

- Automotive, Electrical, Machinery, Industrial Equipment

- Components

- Customized Press Parts

- Other Features

- Corrosion Resistant, Accurate Dimensions, High Strength

- Shape

- Round, Rectangle, Square, As Per Design

- Material

- Stainless Steel, Mild Steel, Aluminum, Brass (as per customer requirement)

- Surface Finishing

- Zinc Plated, Powder Coated, Polished, Anodized

Customized Press Parts Trade Information

- Minimum Order Quantity

- 500 Pieces

- Supply Ability

- 300000 Pieces Per Month

- Delivery Time

- 30 Days

About Customized Press Parts

Discover the new release in engineering solutions with our Customized Press Partscrafted using renowned manufacturing processes like stamping, punching, deep drawing, and forming. These enviable components offer a phenomenal tolerance of 0.1 mm or as specified, ensuring precision for every project. Available in various materials, finishes, and shapes, our products are corrosion resistant and boast accurate dimensions and high strength. With customization available per client drawing and a variety of mounting and packaging options, simply Add to Cart for access to exceptional quality at competitive prices. Manufactured, exported, and supplied from India.

Versatile Usage & Industrial Applications

Customized Press Parts are widely used in the automotive, electrical, machinery, and industrial equipment sectors, owing to their phenomenal load capacity and high strength. Known for enviable corrosion resistance and precise dimensions, these components are favored by professionals and industry leaders worldwide. Utilized by manufacturers and engineers for both specialized and routine tasks, our parts provide flexible solutions tailored for a diverse range of applications, contributing to enhanced performance and reliability.

Reliable Delivery, Stock, and Certifications

Our Customized Press Parts are delivered through stock ready for immediate dispatch to both domestic and international markets. With reputable FOB ports across major Indian cities, all orders are shipped with recognized quality certifications. Customers can expect timely delivery, typically within 730 business days, depending on order size and customization. Each shipment is meticulously packaged in carton or wooden boxes, ensuring products reach you in pristine condition, ready for efficient installation and use.

Versatile Usage & Industrial Applications

Customized Press Parts are widely used in the automotive, electrical, machinery, and industrial equipment sectors, owing to their phenomenal load capacity and high strength. Known for enviable corrosion resistance and precise dimensions, these components are favored by professionals and industry leaders worldwide. Utilized by manufacturers and engineers for both specialized and routine tasks, our parts provide flexible solutions tailored for a diverse range of applications, contributing to enhanced performance and reliability.

Reliable Delivery, Stock, and Certifications

Our Customized Press Parts are delivered through stock ready for immediate dispatch to both domestic and international markets. With reputable FOB ports across major Indian cities, all orders are shipped with recognized quality certifications. Customers can expect timely delivery, typically within 730 business days, depending on order size and customization. Each shipment is meticulously packaged in carton or wooden boxes, ensuring products reach you in pristine condition, ready for efficient installation and use.

FAQs of Customized Press Parts:

Q: How are customized press parts manufactured to ensure high strength and accuracy?

A: Our customized press parts are produced using advanced processes such as stamping, punching, deep drawing, and forming. Each stage is conducted under strict quality control to maintain tight tolerances of 0.1 mm, ensuring precise dimensions and remarkable strength.Q: What materials and surface finishes are available for these press parts?

A: We offer press parts in materials like stainless steel, mild steel, aluminum, and brass according to customer requirements. Surface finishes include zinc plating, powder coating, nickel plating, chrome plating, anodizing, polishing, and various electroplating techniques for superior durability and resistance.Q: When can customers expect delivery after placing an order?

A: Depending on the volume and customization required, most orders are dispatched within 7 to 30 business days from stock ready in our facility. Delivery timelines are always communicated and coordinated for both domestic and international shipments.Q: Where can these customized press parts be applied?

A: Our parts are ideal for integration into automotive components, electrical enclosures, machinery, and industrial equipment, owing to their exceptional strength, load capacity (up to 500 kg or customized), and enviable reliability in demanding environments.Q: What is the process for ordering specialized press parts tailored to my requirements?

A: To order, simply share your design or specifications with us. Our engineering team will review and propose customization options. Once confirmed, advanced manufacturing and careful packaging ensure your order meets all technical and application needs.Q: How does customization benefit my business or application?

A: Customization allows you to specify dimensions, materials, holes, slots, and finishes, achieving perfect compatibility with your systems and greater performance, efficiency, and cost-effectiveness in your final assembly or equipment.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Press Parts Category

Metal Press Parts

Price 5 INR / Piece

Minimum Order Quantity : 500 Pieces

Load Capacity : Up to 500 kg (Depending on design)

Hole Size : 3 mm to 20 mm (Custom available)

Thickness : 0.5 mm to 5 mm

Components : Brackets, Clamps, Fixing Plates, Customized Press Sections

Sheet Press Parts

Price 5 INR / Piece

Minimum Order Quantity : 500 Pieces

Load Capacity : Up to 1000 kg depending on design

Hole Size : Customizable, typically 5 mm to 25 mm

Thickness : 1 mm to 10 mm

Components : Sheet Press Parts

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS