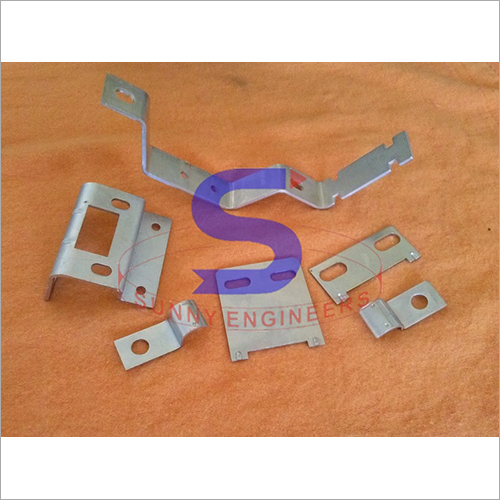

Customized Sheet Metal Brackets

Price 5 INR/ Piece

Customized Sheet Metal Brackets Specification

- Shape

- L-Shape, U-Shape, Custom Shapes Available

- Components

- Bracket Body, Mounting Holes

- Mount Type

- Wall Mount, Panel Mount, Floor Mount

- Coating Type

- Powder Coated, Zinc Plated, Anodized

- Surface Finishing

- Smooth, Polished

- Usage

- Mounting, Supporting, Holding Components

- Hole Size

- Custom; Typically 3 mm - 15 mm

- Weight

- Varies by size and material (approx. 0.1 kg - 5 kg)

- Application

- Industrial Machinery, Electrical Panels, Architecture

- Dimension (L*W*H)

- Custom as per drawing / requirement

- Material

- Mild Steel, Stainless Steel, Aluminum

- Tolerance

- 0.05 mm

- Thickness

- 0.8 mm - 5 mm

- Capacity

- Load dependent on material & design; typically up to 100 kg

- Surface Treatment

- Powder Coating, Galvanized, Anodized

- Making Process

- Laser Cutting, CNC Bending, Welding, Punching

- Installation

- Easy Installation, Pre-drilled holes

- Edge Type

- Deburred/Smooth

- Corrosion Resistance

- High (depends on surface treatment)

- Packaging Type

- Bubble Wrap, Carton Box

- Production Capacity

- 10,000 pieces/month

- OEM Service

- Available

- Color Options

- Black, Silver, Custom Colors Available

Customized Sheet Metal Brackets Trade Information

- Minimum Order Quantity

- 500 Pieces

- Supply Ability

- 300000 Pieces Per Month

- Delivery Time

- 30 Days

About Customized Sheet Metal Brackets

Attaining specialization in this field, we are manufacturing and supplying various types of items to our clients. Here our firm is providing Mild Steel Components which are used in mechanical and electrical applications. We manufactured the same with high quality mild steel with the help of innovative technology. They hold the features like high durability, rust and corrosion resistance in nature. We deliver these Mild Steel Components at reasonable price rate within promised time frame.

Specification

Elongation | 20% |

Usage/Application | Automotive And Industrial |

Brand | Sunny |

Material | Steel, Iron |

Surface Finish | Polished |

Packaging Type | Box |

Hardness | 71 HRC |

Features | Corrosion Resistant |

Tailored Brackets for Every Project

Whether you require brackets for industrial machinery, architecture, or electrical panels, we offer solutions crafted to your specifications. Our manufacturing processlaser cutting, CNC bending, welding, and punchingensures precision and reliability for demanding applications. Choose from wall, floor, or panel mounting options to suit your installation requirements.

Superior Surface Treatments and Color Choices

Select from a variety of corrosion-resistant finishes, including powder coating, galvanizing, or anodizing, and several color options such as black, silver, or any custom shade. These treatments enhance durability and ensure your brackets maintain a premium look and performance over time, even in challenging environments.

FAQs of Customized Sheet Metal Brackets:

Q: How can the dimensions and shape of the sheet metal brackets be customized?

A: We manufacture brackets based on your provided drawings or requirements, offering custom dimensions (length, width, height), thickness between 0.8 mm and 5 mm, and various shapes including L-shape, U-shape, or a tailored design.Q: What is the process involved in making these customized brackets?

A: Our brackets are produced using advanced techniques such as laser cutting, CNC bending, welding, and punching. This ensures high accuracy (0.05 mm tolerance) and smooth, deburred edges for safe handling and easy installation.Q: Where are these sheet metal brackets commonly used?

A: These brackets are widely used in industrial machinery, electrical panels, architectural projects, and for mounting or supporting various components in diverse settings.Q: What color and surface treatment options are available?

A: Customers can choose from standard colors like black and silver, as well as custom shades. Surface treatments include powder coating, galvanized plating, or anodizing, all of which provide high corrosion resistance.Q: How easy is the installation, and what mounting options are provided?

A: Installation is straightforward thanks to pre-drilled holes and deburred edges. We offer different mounting options, including wall, panel, and floor mounts, to fit your application perfectly.Q: What is the typical load capacity of these brackets?

A: Load capacity depends on material choice and bracket design, with most configurations supporting up to 100 kg per bracket.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sheet Metal Components Category

Press Parts

Price 5 INR / Piece

Minimum Order Quantity : 500 Pieces

Components : Plate, Bush, Pin, Spacer etc.

Tolerance : 0.01 mm

Shape : Rectangular / Circular / Custom

Coating Type : AntiRust / Zinc

Precision Pressed Parts

Price 5 INR / Piece

Minimum Order Quantity : 500 Pieces

Components : Custom Configuration

Tolerance : 0.02 mm

Shape : Rectangular

Coating Type : Anticorrosion Coating

Sheet Metal Pressed Component

Price 5 INR / Piece

Minimum Order Quantity : 500 Pieces

Components : Brackets, Clamps, Connectors, Mounting Plates

Tolerance : 0.05mm

Shape : Rectangular, Custom shapes available

Coating Type : Zinc, Nickel, Powder or as specified

Sheet Metal Brackets

Price 5 INR / Piece

Minimum Order Quantity : 500 Pieces

Components : Bracket body with prepunched holes

Tolerance : 0.2 mm

Shape : LShaped / Right Angle

Coating Type : Galvanized or Painted

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS