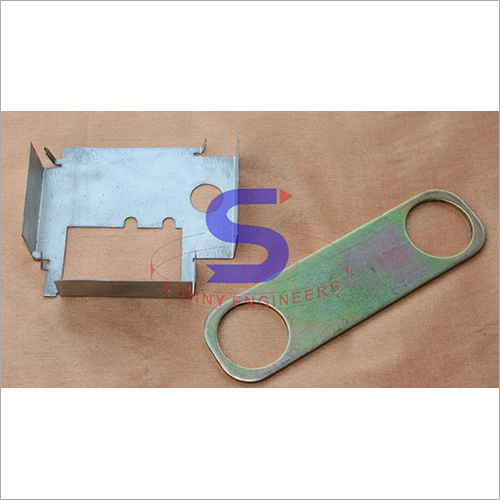

Automobile Press Parts

Price 5 INR/ Piece

Automobile Press Parts Specification

- Hole Size

- 10 mm

- Coating Type

- Anti-Corrosive Coating

- Surface Finishing

- Smooth / Polished

- Application

- Automobile Body & Chassis

- Mount Type

- Bolt-on

- Components

- Bracket, Plate

- Weight

- Approx. 0.8 kg

- Usage

- Automotive Parts Assembly

- Shape

- Rectangular with Cut-outs

- Dimension (L*W*H)

- 150 mm x 80 mm x 5 mm

- Material

- Mild Steel (MS)

- Tolerance

- 0.05 mm

- Thickness

- 5 mm

- Capacity

- Suitable for 20-150 Ton Press

- Surface Treatment

- Zinc Plated

- Making Process

- Stamping & Pressing

- OEM Service

- Available

- Corrosion Resistance

- Yes

- Edge Type

- Deburred

- Punching Accuracy

- High Precision

- Production Technique

- Cold Forming

- Colour

- Silver

- Machinability

- High

- MOQ

- 500 Pieces

Automobile Press Parts Trade Information

- Minimum Order Quantity

- 500 Pieces

- Supply Ability

- 300000 Pieces Per Month

- Delivery Time

- 30 Days

About Automobile Press Parts

Owing to our expertise in this domain, we offer Automobile Press Parts that is produced by using quality tested components with the help of advanced methodology. This item is utilized in the assembling business to misshape a work piece under high tension. It is acclaimed for its high performance, quality and durability. Our offered items are tested on the various quality parameters before final dispatch. The delivery of this Automobile Press Parts is done by us within the promised time frame.

Specification

Features | Corrosion Resistance |

Usage/Application | Automotive And Industrial |

Brand | Sunny |

Material | Steel, Iron |

Packaging Type | Box |

Thickness | 2-9 mm |

Superior Corrosion Resistance

Thanks to a zinc-plated, anti-corrosive coating on mild steel material, our automobile press parts effectively resist oxidation and environmental damage. This ensures long-lasting performance especially in demanding automotive environments, extending the lifespan of each component. The smooth, polished surface adds further protection against wear and corrosion, making these parts reliable for both body and chassis applications.

Precision Cold Forming Process

Each component is manufactured using advanced cold forming, stamping, and pressing techniques. This allows for high dimensional accuracy, deburred edges, and consistent quality across batches. Our process delivers parts with tight tolerances of 0.05 mm and exact hole sizes for efficient assembly, ensuring seamless integration into automotive production lines.

OEM Service & Customization

We provide OEM solutions tailored to specific client requirements, including custom dimensions, shapes, and surface finishes. With a minimum order quantity of 500 pieces, manufacturers and exporters are assured of scalable production capabilities. Our team delivers precision-engineered brackets and plates that meet global quality standards for the automotive industry.

FAQs of Automobile Press Parts:

Q: How are these automobile press parts manufactured for high precision and durability?

A: The press parts are produced using cold forming, stamping, and pressing techniques, followed by deburring and a zinc-plated anti-corrosive coating. This process ensures high machinability, accurate dimensions, and consistent quality for automotive body and chassis assemblies.Q: What are the primary benefits of using zinc-plated, mild steel press parts in automobiles?

A: Zinc plating provides superior corrosion resistance, preventing rust and wear, while mild steel offers robust strength. The smooth polished finish and deburred edges result in components that last longer and fit seamlessly into automotive assemblies, improving overall reliability.Q: How does the OEM service work for customized automobile press parts?

A: OEM service allows clients to request tailored components based on their specific needs, such as dimensions, cut-outs, or surface treatments. After consultation, we manufacture the parts under strict quality controls, ensuring compatibility with each customers automotive application.Q: When can these press parts be integrated into an automotive assembly line?

A: Once manufactured and inspected for high precision and tolerance, the press parts can be delivered and immediately integrated into body and chassis assembly lines where bolt-on mounting is required. Their accurate dimensions streamline the installation process.Q: Where are these automobile press parts typically used?

A: These parts are primarily employed in automotive body and chassis assembly, serving as brackets, plates, or structural supports. Their robust construction and corrosion resistance make them suitable for both commercial and passenger vehicles.Q: What is the minimum order quantity for these press parts, and who can order them?

A: The minimum order quantity is 500 pieces. We cater to manufacturers, exporters, and suppliers in the automotive industry, especially those requiring bulk quantities for production and export from India.Q: How does the high punching accuracy benefit the end user in automotive applications?

A: High punching accuracy ensures each component fits exactly into its intended assembly location, improving structural integrity and reducing installation errors. This precision is vital for efficient automated production lines and long-term vehicle reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sheet Metal Components Category

Precision Press Parts

Price 5 INR / Piece

Minimum Order Quantity : 500 Pieces

Thickness : 0.2 mm to 8 mm

Application : Assembly components, electrical enclosures

Mount Type : Through hole or slot mount

Components : Customized per drawing

Precision Pressed Components

Price 5 INR / Piece

Minimum Order Quantity : 500 Pieces

Thickness : 0.5 mm 5 mm

Application : Automotive, Electronics, Industrial machinery

Mount Type : Panel mount, Surface mount

Components : Brackets, Clips, Covers

Deep Drawn Components

Price 5 INR / Piece

Minimum Order Quantity : 500 Pieces

Thickness : 0.5 mm to 2.5 mm

Application : Enclosures, Covers, Housings

Mount Type : Panel Mount / Surface Mount

Components : Caps, Cases, Shells

Progressive Tool Components

Price 5 INR / Piece

Minimum Order Quantity : 500 Pieces

Thickness : Up to 60 mm

Application : Automotive, Electrical, Industrial

Mount Type : Standard, Custom Mount

Components : Die sets, Punches, Inserts, Holder, Stripper plates

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free