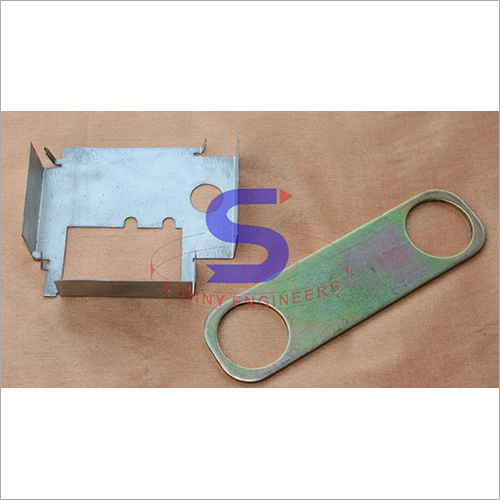

Automotive Brackets

Price 5 INR/ Piece

Automotive Brackets Specification

- Hole Size

- 9 mm

- Shape

- L-Shaped

- Dimension (L*W*H)

- 120mm x 60mm x 30mm

- Application

- Passenger Cars, SUVs, Commercial Vehicles

- Weight

- 220 g

- Mount Type

- Bolt-On

- Coating Type

- Epoxy Coating

- Components

- Bracket Body, Mounting Holes

- Surface Finishing

- Matte Black

- Usage

- Automotive Body and Engine Mounting

- Material

- Cold Rolled Steel

- Tolerance

- 0.2 mm

- Thickness

- 3 mm

- Capacity

- Supports up to 25 kg

- Surface Treatment

- Powder Coated

- Making Process

- Precision Stamping and CNC Machining

Automotive Brackets Trade Information

- Minimum Order Quantity

- 500 Pieces

- Supply Ability

- 300000 Pieces Per Month

- Delivery Time

- 30 Days

About Automotive Brackets

Assembling and providing an exhaustive scope of things, we have arisen as the most ideal choice on the lookout. The provided Automotive Brackets that is utilized for different purposes like continuing/to store material or mechanical supplies. This item is useful in supporting pipelines mounted on dividers. It is profoundly requested on the lookout for its toughness and hostile to consumption nature of the equivalent. The conveyance of this Automotive Brackets is done by us at practical costs.

Outstanding Durability & Corrosion Protection

With an advanced epoxy powder coating, our automotive brackets demonstrate remarkable corrosion resistance, withstanding up to 500 hours in salt spray tests. Their robust design guarantees consistent performance in environments with high humidity or exposure to road salts. Crafted from cold rolled steel and engineered for strength, these brackets offer reliability under demanding automotive conditions.

Precision Engineering for Diverse Applications

Each bracket is manufactured through advanced precision stamping and CNC machining, yielding tight dimensional tolerances (0.2 mm). The L-shaped form and bolt-on mount type make these brackets suitable for a wide range of body and engine mounting scenarios across different vehicle types, from passenger cars to heavy-duty commercial vehicles.

Customizable for OEM Integration

We offer bespoke manufacturing, allowing customization in dimensions, shape, and surface coatings to suit specific OEM design and application requirements. Our process ensures seamless integration with brand guidelines and technical specifications, making these brackets a preferred choice for manufacturers seeking tailored component solutions.

FAQs of Automotive Brackets:

Q: How are the automotive brackets tested for corrosion resistance?

A: Our brackets undergo rigorous salt spray testing, ensuring up to 500 hours of resistance to corrosion as per industry standards. This process simulates harsh automotive environments and provides confidence in long-term durability, particularly in areas exposed to moisture and road salts.Q: What makes these brackets suitable for vehicle body and engine mounting?

A: These brackets are constructed from cold rolled steel with a 3 mm thickness, providing high strength and rigidity. With a capacity to support up to 25 kg and precision-engineered bolt-on holes, they are ideal for securely mounting components in both body and engine applications of cars, SUVs, and commercial vehicles.Q: When should I consider customizing the bracket features for my project?

A: Customization is recommended when specific dimensional, shape, or coating requirements are necessary for optimal fit and performance with your OEM or aftermarket applications. We provide flexibility in design to meet unique engineering and integration needs.Q: Where can these brackets be used within a vehicle?

A: Designed for versatile mounting, these brackets are suitable for numerous locations in vehicle bodies and engine bays. Their L-shaped design and dimensional flexibility allow them to fit diverse automotive mounting points, supporting a wide array of assembly configurations.Q: What is the production process for these automotive brackets?

A: Manufacturing involves precision stamping and CNC machining, which ensure tight tolerances and consistent quality. The process ends with a powder coating and epoxy application, providing both aesthetic finish (matte black) and protective benefits.Q: How does the surface treatment benefit the brackets performance?

A: The epoxy-based powder coating delivers a hard, matte black surface that enhances corrosion resistance and heat endurance (up to 180C), extending the service life of the bracket under demanding automotive conditions.Q: What packaging options are available for these brackets?

A: Each bracket is packed individually in a polybag for protection against scratches, and multiple units are shipped together in sturdy cartons, ensuring safe transit and easy handling during bulk supply.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

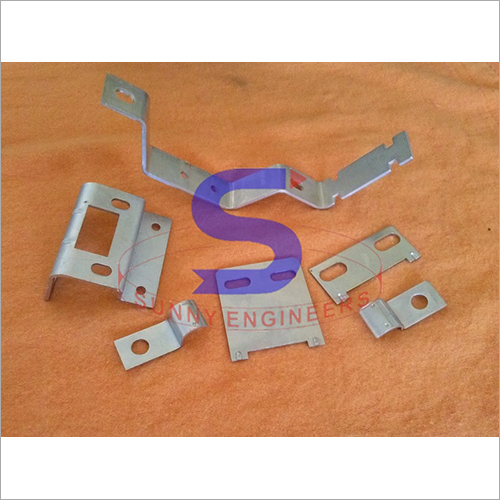

More Products in Sheet Metal Components Category

Precision Pressed Components

Price 5 INR / Piece

Minimum Order Quantity : 500 Pieces

Mount Type : Panel mount, Surface mount

Weight : Varies by dimension

Dimension (L*W*H) : Custom as per requirement

Application : Automotive, Electronics, Industrial machinery

Automotive Metal Stamping

Price 5 INR / Piece

Minimum Order Quantity : 500 Pieces

Mount Type : BoltOn, WeldOn

Weight : As per design, ranges from a few grams to several kilograms

Dimension (L*W*H) : Customizable as per drawing/specification

Application : Chassis, Body Panels, Brackets, Engine Components

Customized Sheet Metal Brackets

Price 5 INR / Piece

Minimum Order Quantity : 500 Pieces

Mount Type : Wall Mount, Panel Mount, Floor Mount

Weight : Varies by size and material (approx. 0.1 kg 5 kg)

Dimension (L*W*H) : Custom as per drawing / requirement

Application : Industrial Machinery, Electrical Panels, Architecture

Automotive Brackets

Price 5 INR / Piece

Minimum Order Quantity : 500 Pieces

Mount Type : BoltOn

Weight : 350 g

Dimension (L*W*H) : 120mm x 80mm x 40mm

Application : Automotive Assemblies

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free