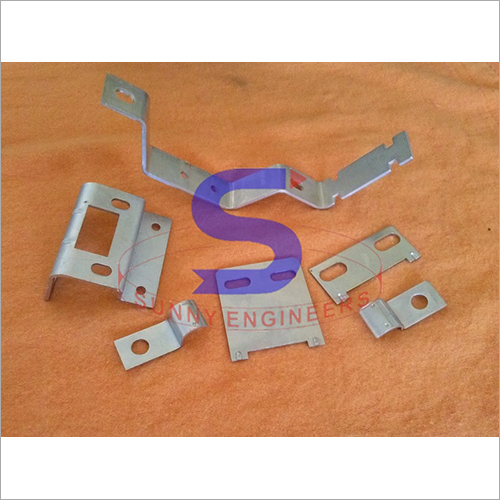

Precision Sheet Metal Components

Price 5 INR/ Piece

Precision Sheet Metal Components Specification

- Hole Size

- Customized as per drawing

- Dimension (L*W*H)

- Custom as per requirement

- Usage

- Electrical, Electronics, Automotive and Machinery

- Application

- Enclosures, Cabinets, Brackets, Panels, Mounts

- Shape

- Rectangular, Square, Circular, Custom

- Surface Finishing

- Smooth, Matte, Glossy, Brushed

- Components

- Brackets, Covers, Chassis, Plates, Holders

- Coating Type

- Electroplating, Powder Coating, Painting

- Mount Type

- Panel Mounted, Wall Mounted, Floor Mounted

- Weight

- As per component design and size

- Material

- Stainless Steel, Mild Steel, Aluminum

- Tolerance

- 0.05 mm

- Thickness

- 0.5 mm to 6 mm

- Capacity

- High volume production capability

- Surface Treatment

- Zinc Plating, Powder Coating, Anodizing

- Making Process

- Laser Cutting, CNC Punching, Bending, Welding

Precision Sheet Metal Components Trade Information

- Minimum Order Quantity

- 500 Pieces

- Supply Ability

- 300000 Pieces Per Month

- Delivery Time

- 30 Days

About Precision Sheet Metal Components

Leveraging on the expertise of our dexterous personnel, we are involved in manufacturing and supplying a premium quality metal components to our valuable patrons. Here our firm is providing Precision Sheet Metal Components that finds their applications in the mechanical and electrical appliances. All the provided items are tested on the various quality parameters before dispatching them from our premises. The delivery of these Precision Sheet Metal Components is done by us at cost-effective prices.

Specification

Corrosion Resistance | Yes |

Usage/Application | Industrial |

Thickness | 1-5 mm |

Brand | Sunny |

Size | up to 6.0 mm |

Packaging Type | Box |

Tailored to Your Requirements

We offer fully customizable sheet metal solutions to accommodate any dimension, color, shape, or application you require. With support for CAD/CAM drawings and an extensive range of finishessmooth, matte, glossy, brushedeach component is delivered to your exact specifications. Our team ensures a seamless process, from design to packaging, guaranteeing you receive optimal quality and performance.

Unparalleled Quality and Standards

Our components are crafted under stringent quality control, adhering to RoHS and ISO standards. Each piece boasts a high level of corrosion resistance thanks to advanced surface treatments, and precision is maintained with tight tolerances of 0.05 mm. You can rely on consistent, durable parts whether you order a single prototype or require high-volume production.

FAQs of Precision Sheet Metal Components:

Q: How are the precision sheet metal components customized to meet my specific requirements?

A: We offer customization across dimensions, colors, shapes, and mounting options. You can provide CAD or CAM drawings for exact specifications, and we manufacture components such as brackets, covers, chassis, and panels to your requirements using advanced fabrication processes.Q: What materials and surface finishes are available for these components?

A: Our components are manufactured from stainless steel, mild steel, or aluminum, with surface treatments including zinc plating, powder coating, anodizing, painting, or electroplating. Finish options include smooth, matte, glossy, and brushed, allowing you to select the best combination for your application.Q: When can I expect my order to be delivered?

A: Lead times typically range from 7 to 21 days, depending on the order quantity and customization requirements. Each component is packed in custom protective packaging to ensure safe delivery.Q: Where can these precision sheet metal components be used?

A: These components are ideal for use in electrical enclosures, electronic cabinets, automotive mounts, industrial brackets, panels, and other machined assemblies in various sectors such as electronics, automotive, and machinery.Q: What is the manufacturing process for these components?

A: Our manufacturing processes include laser cutting, CNC punching, bending, welding, and surface finishing. Careful edge treatments like deburring and chamfering ensure each component has a high-quality finish.Q: How do I benefit from the high corrosion resistance and quality standards?

A: All components are treated for high corrosion resistance through appropriate materials and coatings, and strict adherence to RoHS and ISO standards ensures durable, safe, and compliant products that maintain their performance under demanding conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sheet Metal Components Category

Precision Pressed Parts

Price 5 INR / Piece

Minimum Order Quantity : 500 Pieces

Material : Stainless Steel

Hole Size : 2.5 mm

Dimension (L*W*H) : 45 mm x 30 mm x 5 mm

Making Process : Other, Precision Stamping

Precision Press Parts

Price 5 INR / Piece

Minimum Order Quantity : 500 Pieces

Material : Other, Highgrade stainless steel

Hole Size : From 1 mm onwards

Dimension (L*W*H) : Customizable as per requirements

Making Process : Other, Precision stamping and pressing

Automotive Press Parts

Price 5 INR / Piece

Minimum Order Quantity : 500 Pieces

Material : Other, Mild Steel (MS), Stainless Steel (SS), Aluminum

Hole Size : 2 mm to 18 mm (as per design)

Dimension (L*W*H) : Custom as per drawing / requirement

Making Process : Other, Progressive Die Stamping / Pressing / Punching

Customized Sheet Metal Brackets

Price 5 INR / Piece

Minimum Order Quantity : 500 Pieces

Material : Other, Mild Steel, Stainless Steel, Aluminum

Hole Size : Custom; Typically 3 mm 15 mm

Dimension (L*W*H) : Custom as per drawing / requirement

Making Process : Other, Laser Cutting, CNC Bending, Welding, Punching

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free