Welded Shell

Price 5 INR/ Piece

Welded Shell Specification

- Components

- Shell body, Nozzle openings, Support rings

- Mount Type

- Horizontal / Vertical Mount

- Weight

- Depends on dimension and material

- Coating Type

- Anti-corrosive coating (if specified)

- Dimension (L*W*H)

- Custom/As per requirement

- Application

- Heat Exchanger / Pressure Vessel / Industrial Storage

- Shape

- Cylindrical / Custom

- Surface Finishing

- Smooth / Mat Finishing

- Usage

- Mechanical / Industrial Equipment

- Hole Size

- As per nozzle/flange requirement

- Material

- Stainless Steel / Mild Steel

- Tolerance

- 1 mm

- Thickness

- 5 to 25 mm

- Capacity

- As per design/application

- Surface Treatment

- Polished / Painted

- Making Process

- Welded Fabrication

- Standards Followed

- ASME / IS / DIN / Custom

- Operating Temperature

- Up to 350°C (depending on material)

- Corrosion Resistance

- High (for stainless steel)

- End Type

- Flat/ Dished/ Flanged Ends

- Testing Standard

- Hydrostatic / Radiographic (on demand)

- Material Grade

- SS304 / SS316 / IS2062 (other grades on request)

- Operating Pressure

- Up to 20 bar (customizable)

- Welding Type

- TIG / MIG / SAW

Welded Shell Trade Information

- Minimum Order Quantity

- 500 Pieces

- Supply Ability

- 300000 Pieces Per Month

- Delivery Time

- 30 Days

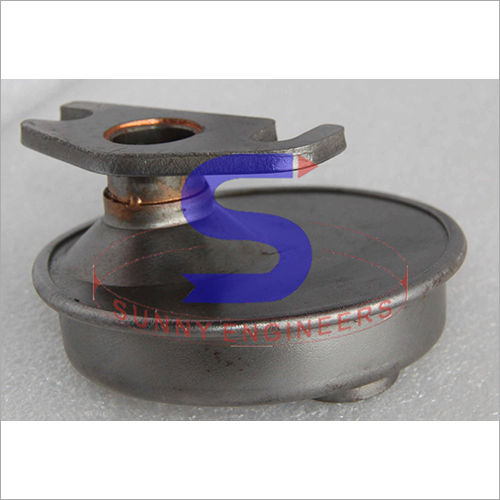

About Welded Shell

Holding intensive information and customer driven methodology, we are considered as the confided in maker and provider of different sorts of items. Here our firm is supplying Welded Shell that is manufactured by using high quality required materials with the help of sophisticated technology under the supervision of our experts. This item is best to eliminate any slag considerations (still under preheat), and the weld finished from within surface. We supply this Welded Shell at market driving cost.

Customized Versatility for Industrial Needs

Each welded shell is tailor-made for your application, ranging from cylindrical to custom shapes and dimensions. Choose from flat, dished, or flanged ends, various material grades, and mounting options to match your specific operational environment. All components and openings are designed and fabricated to exact client specifications with tolerance as tight as 1 mm.

Quality Assurance and International Standards

We follow stringent quality protocols, including hydrostatic and radiographic testing on demand, ensuring reliable performance under pressure and temperature extremes. Manufacturing aligns with global standards such as ASME, IS, and DIN. Our shells feature polished or painted finishes and anti-corrosive coatings for long-term durability, especially in corrosive atmospheres.

Efficient Solutions for Industrial Applications

Ideal for use in heat exchangers, pressure vessels, and industrial storage, our welded shells help optimize mechanical and process efficiency. With high corrosion resistance and robust fabrication, these vessels contribute to safe, reliable operation across a variety of mechanical and industrial setups, making them indispensable for modern plant infrastructure.

FAQs of Welded Shell:

Q: How is the welded shell customized for different industrial applications?

A: We offer customization for the welded shell in terms of dimensions, material grade, end types, and capacity. Clients can request specific designs, shapes, and mounting styles (horizontal or vertical) to match their particular process, equipment, or site requirements.Q: What materials are available for manufacturing these welded shells?

A: Our welded shells can be manufactured from stainless steel grades SS304 and SS316, as well as mild steel (IS2062). Additional material grades are available upon request to cater to unique operational needs and environments.Q: What testing standards do welded shells comply with?

A: We conduct hydrostatic testing for all shells, with radiographic inspection available on demand. The manufacturing process adheres to recognized standards such as ASME, IS, and DIN, or can be customized to meet client-specific codes.Q: When should I specify anti-corrosive coating for my welded shell?

A: Anti-corrosive coatings are recommended for shells operating in environments prone to rust or chemical exposure. These coatings enhance longevity and maintain integrity, especially for outdoor or corrosive industrial settings.Q: Where are these welded shells typically used?

A: Our welded shells serve extensively in mechanical and industrial equipment, most commonly found in heat exchangers, pressure vessels, and industrial storage systems across sectors such as chemical, energy, and manufacturing.Q: What is the typical process for fabricating a welded shell?

A: Fabrication involves welded assembly using TIG, MIG, or SAW techniques, followed by precise fitting of shell bodies, nozzle openings, and support rings. Rigorous testing and surface finishing are applied as per client specification and standard requirements.Q: What are the primary benefits of choosing your welded shells?

A: Selecting our product means benefitting from high corrosion resistance, customizable designs, adherence to major quality standards, and long service life. These features translate into safer operations and optimized mechanical performance for industrial users.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sheet Metal Assemblies Category

Stamping Parts

Price 5 INR / Piece

Minimum Order Quantity : 500 Pieces

Components : Customized as per drawing

Mount Type : Screw or Bolt Mount

Material : Other, Stainless Steel / Mild Steel / Brass / Aluminum

Making Process : Other, Stamping, Punching, Forming

Metal Strainer

Price 5 INR / Piece

Minimum Order Quantity : 500 Pieces

Components : Handle, Rim, Mesh Body

Mount Type : Handheld

Material : Stainless Steel

Making Process : Other, Deep Drawing & Perforating

Deep Drawn Parts

Price 5 INR / Piece

Minimum Order Quantity : 500 Pieces

Components : Shells, Covers, Cases

Mount Type : Panel Mount, Screw Mount

Material : Other, Stainless Steel, Mild Steel, Aluminum

Making Process : Other, Deep Drawing

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS