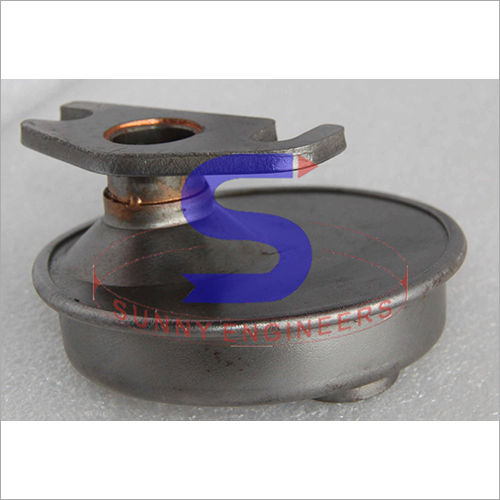

Deep Drawn Parts

Price 5 INR/ Piece

Deep Drawn Parts Specification

- Mount Type

- Panel Mount, Screw Mount

- Dimension (L*W*H)

- Customizable as per design requirements

- Surface Finishing

- Smooth, Matt, Glossy

- Weight

- Varies as per size and material

- Components

- Shells, Covers, Cases

- Application

- Enclosures, Motor Parts, Electrical Boxes

- Hole Size

- Custom as per order

- Usage

- Industrial, Automotive, Electrical

- Shape

- Round, Square, Rectangular, Custom

- Coating Type

- Zinc Plated, Epoxy Coated

- Material

- Stainless Steel, Mild Steel, Aluminum

- Tolerance

- 0.05 mm

- Thickness

- 0.3 mm to 3 mm

- Capacity

- Up to 500 tons

- Surface Treatment

- Galvanized, Polished, Powder Coated

- Making Process

- Deep Drawing

Deep Drawn Parts Trade Information

- Minimum Order Quantity

- 500 Pieces

- Supply Ability

- 300000 Pieces Per Month

- Delivery Time

- 30 Days

About Deep Drawn Parts

As a reputed manufacturer and supplier of qualitative Brazed Parts that is used to join materials in such various applications as gems, high-temperature pottery, kitchen cutlery, restroom fixtures, car motors, stream airplane motors and cooling frameworks. It is produced by using required materials and innovative technology under the supervision of our industry experts which ensures the durability of the same. The supply of this Brazed Parts is done by us at genuine price rate within promised time frame.

Specification

Tolerance | +/- 0.05 mm |

Brand | Sunny |

Usage/Application | Industrial |

Finishing And Coating | Zinc Plating |

Material | Iron, Stainless Steel |

Size | 2-50 mm |

Packaging Type | Carton Box |

Corrosion Resistance | Yes |

Surface Finishing | Polished |

Precision Solutions for Demanding Applications

Our deep drawn parts ensure high accuracy and reliability for critical industries such as automotive, electrical, and industrial manufacturing. With a production capability of up to 500 tons and drawing force up to 500 kN, we deliver components for enclosures, covers, motor parts, and more. Every part can be customized in terms of dimension, thickness, edge type, and surface finish, supporting even the most stringent design requirements.

Quality, Corrosion Resistance, and Versatile Finishing

Leveraging ISO 9001:2015 certified production practices, our components feature high corrosion resistance with options such as galvanization, powder coating, and polishing. Surface finishing is available in smooth, matt, or glossy to suit aesthetic and functional needs. Each part is rigorously tested for dimensional and material accuracy, ensuring a dependable, long-lasting product.

FAQs of Deep Drawn Parts:

Q: How are deep drawn parts manufactured to achieve high precision and strength?

A: Our parts are manufactured using advanced deep drawing processes, either single or multi-stage, with a drawing force of up to 500 kN. This method ensures uniform structure, tight tolerances (0.05 mm), and excellent mechanical strength, meeting various industrial and automotive requirements.Q: What customization options are available for these deep drawn components?

A: We offer extensive customization on all parametersincluding material selection (stainless steel, mild steel, aluminum), dimensions (LWH), thickness (0.33 mm), hole sizes, edge types, mount types, and surface finishes. Coatings, colors, and specialization for unique applications can also be provided as per customer specifications.Q: When can customers expect delivery after placing an order for deep drawn parts?

A: Standard lead time for our deep drawn components is 24 weeks after order confirmation and design approval. Expedited production and shipping options are available for urgent requirements.Q: Where are your deep drawn parts typically used, and which industries benefit most from them?

A: Our products serve a range of industries, including automotive, electrical, and general industrial sectors. Common applications include enclosures, motor parts, electrical boxes, and custom covers, offering versatility and durability in demanding conditions.Q: What are the key benefits of choosing your deep drawn parts with advanced surface treatments?

A: Our parts feature high corrosion resistance and excellent durability, thanks to options such as galvanization, powder coating, and polishing. This extends component lifespan, maintains aesthetic appeal, and ensures reliable performance, even in harsh environments from -40C to +150C.Q: How is quality assured in the manufacturing of these parts?

A: Quality is assured through ISO 9001:2015 certified processes, thorough dimensional and material inspections, and rigorous testing at multiple production stages. Each batch undergoes both automated and manual inspections to meet specified tolerance and material standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sheet Metal Assemblies Category

Stamping Parts

Price 5 INR / Piece

Minimum Order Quantity : 500 Pieces

Material : Other, Stainless Steel / Mild Steel / Brass / Aluminum

Mount Type : Screw or Bolt Mount

Tolerance : 0.05 mm

Surface Finishing : Polished, Coated, Smooth

Welded Shell

Price 5 INR / Piece

Minimum Order Quantity : 500 Pieces

Material : Other, Stainless Steel / Mild Steel

Mount Type : Horizontal / Vertical Mount

Tolerance : 1 mm

Surface Finishing : Smooth / Mat Finishing

Metal Strainer

Price 5 INR / Piece

Minimum Order Quantity : 500 Pieces

Material : Stainless Steel

Mount Type : Handheld

Tolerance : 0.5 mm

Surface Finishing : Mirror Finish

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS