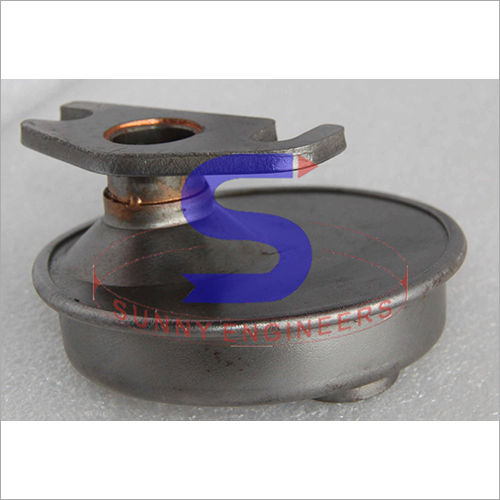

Stamping Parts

Price 5 INR/ Piece

Stamping Parts Specification

- Components

- Customized as per drawing

- Surface Finishing

- Polished, Coated, Smooth

- Hole Size

- 1 mm to 10 mm

- Dimension (L*W*H)

- Customized as per requirement

- Shape

- Rectangular / Customized

- Mount Type

- Screw or Bolt Mount

- Application

- Connectors, Terminals, Mounting Brackets

- Usage

- Electrical, Automotive, Industrial

- Weight

- As per design

- Coating Type

- Electroplating / Powder Coating

- Material

- Stainless Steel / Mild Steel / Brass / Aluminum

- Tolerance

- 0.05 mm

- Thickness

- 0.3 mm to 3.0 mm

- Capacity

- Up to 200 Tons

- Surface Treatment

- Zinc Plated, Nickel Plated, Powder Coated

- Making Process

- Stamping, Punching, Forming

- Color

- Silver

- Minimum Order Quantity

- 500 pieces

- Lead Time

- 2-4 weeks

- Packaging Type

- Corrugated box

- Production Technique

- Progressive die

- Hardness

- HRC 25-30

- Temperature Resistance

- Up to 120°C

- Drawing Format Accepted

- CAD, PDF

- Customization

- Design, logo, dimensions

- Compliance

- RoHS compliant

- OEM Service

- Available

- Edge Type

- Deburred

Stamping Parts Trade Information

- Minimum Order Quantity

- 500 Pieces

- Supply Ability

- 300000 Pieces Per Month

- Delivery Time

- 30 Days

About Stamping Parts

We are in the regular fashion of making good quality Stamping Parts which are widely utilized kick the bucket producing and machining, bringing about incredibly diminished expense. Despite the fact that not as solid as pass on manufactured parts, they were of sufficient quality. All the provided items are tested on the various quality parameters before dispatching them from our premises. Our clients can avail this Stamping Parts by us at fixed prices within promised time period.

Specification

Features | Corrosion Resistance |

Brand | Sunny |

Material | Stainless Steel |

Packaging Type | Box |

Thickness | 1-3 mm |

Tensile Strength | 100-300 Mpa |

Hardness | 55-60 HRC |

Tailored Precision for Industrial Needs

Our stamping parts deliver high accuracy and consistency, tailored to meet custom requirements across various industries. Whether youre seeking mounting brackets, connectors, or terminals, we cater to specific designs, dimensions, and branding, ensuring optimal fit and functionality. Our robust production capacity supports both small and large volume orders with uncompromised quality.

Durable Materials and Superior Finish

Choose from stainless steel, mild steel, brass, or aluminum, all processed to exact tolerances of 0.05 mm. Each part receives a careful finishing treatmentoptions such as zinc plating, nickel plating, powder coating, or polishing ensure enhanced corrosion resistance and a smooth, attractive appearance. Deburred edges guarantee safe handling during installation and use.

Compliance and Reliable Delivery

Our stamping parts comply with RoHS guidelines, making them ideal for global markets and environmentally conscious applications. With a flexible minimum order quantity starting at 500 pieces and a lead time of 2-4 weeks, we ensure timely delivery. Secure corrugated box packaging provides added protection during transit and storage.

FAQs of Stamping Parts:

Q: How are your stamping parts manufactured?

A: Our stamping parts are produced using progressive die techniques, which enable high-speed and precise forming of complex shapes. The process includes stamping, punching, forming, and deburring to ensure consistent quality and safe edges on each part.Q: What materials and surface treatments are available?

A: We offer parts in stainless steel, mild steel, brass, or aluminum, with surface treatments like zinc plating, nickel plating, and powder coating for added corrosion resistance and tailored appearance. Polished and smooth finishes are also available to suit your specific needs.Q: When can I expect delivery after placing my order?

A: Lead times generally range from 2-4 weeks, depending on order quantity and customization requirements. We work to ensure punctual delivery and update clients throughout the production process.Q: Where can these stamping parts be used?

A: Our parts are versatile and suitable for electrical assemblies, automotive components, industrial machinery, and more. Common applications include connectors, terminals, mounting brackets, and other custom-designed components.Q: What is the minimum order quantity and packaging method?

A: The minimum order quantity is 500 pieces. All parts are securely packed in corrugated boxes to ensure damage-free delivery.Q: How do you ensure compliance and quality?

A: All products are RoHS compliant and undergo strict quality checks throughout production, including precise tolerance controls (0.05 mm) and thorough inspection of dimensions, coating, and finishing.Q: What customization options are available for OEM clients?

A: We support full customization including design, logo, dimensions, material, and surface finishing. Clients can submit drawings in CAD, PDF, or other preferred formats for tailored manufacturing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sheet Metal Assemblies Category

Welded Shell

Price 5 INR / Piece

Minimum Order Quantity : 500 Pieces

Usage : Mechanical / Industrial Equipment

Thickness : 5 to 25 mm

Weight : Depends on dimension and material

Coating Type : Anticorrosive coating (if specified)

Deep Drawn Parts

Price 5 INR / Piece

Minimum Order Quantity : 500 Pieces

Usage : Industrial, Automotive, Electrical

Thickness : 0.3 mm to 3 mm

Weight : Varies as per size and material

Coating Type : Zinc Plated, Epoxy Coated

Metal Strainer

Price 5 INR / Piece

Minimum Order Quantity : 500 Pieces

Usage : Straining liquids, rinsing fruits and vegetables

Thickness : 0.5 mm

Weight : 80 g

Coating Type : Uncoated

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS