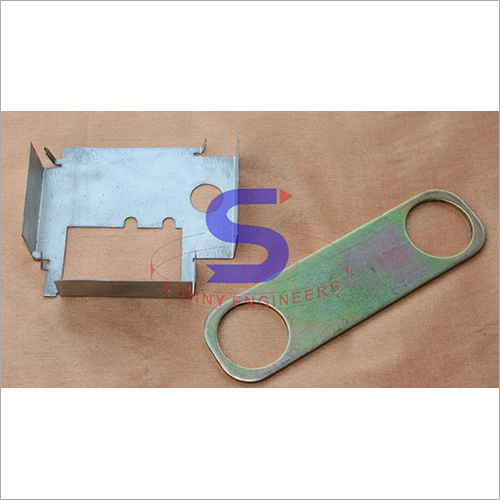

Sheet Metal Stampings

Price 5 INR/ Piece

Sheet Metal Stampings Specification

- Components

- Automotive, Electrical, Electronics Assemblies

- Mount Type

- Panel Mount, Surface Mount, Custom Mount

- Dimension (L*W*H)

- Custom as per requirement

- Usage

- Industrial, Electrical, Automotive, Construction

- Shape

- Rectangular, Square, Circular, Custom

- Application

- Chassis, Brackets, Covers, Panels, Custom Parts

- Surface Finishing

- Smooth, Matte, Glossy, Textured

- Weight

- Varies as per design

- Coating Type

- Zinc Plated, Nickel Plated, Powder Coated

- Hole Size

- As per specification

- Material

- Mild Steel, Stainless Steel, Brass, Copper, Aluminium

- Tolerance

- 0.1 mm

- Thickness

- 0.5 mm to 5 mm

- Capacity

- Up to 500 tons

- Surface Treatment

- Electroplating, Powder Coating, Anodizing, Painting

- Making Process

- Stamping, Punching, Bending, Forming

- Color

- Silver, Metallic Grey, Custom colors possible

- Production Rate

- High-volume and low-volume batch production available

- Corrosion Resistance

- Yes, upon request

- Hardness

- As per material specification

- Cutting Method

- Laser, CNC, Die Cutting

- Lead Time

- 2-4 weeks after order confirmation

- Edge Type

- Deburred, No Sharp Edges

- MOQ

- 500 Pieces

- Packing Type

- Standard Export Carton, Customized Packaging

Sheet Metal Stampings Trade Information

- Minimum Order Quantity

- 500 Pieces

- Supply Ability

- 300000 Pieces Per Month

- Delivery Time

- 30 Days

About Sheet Metal Stampings

Sponsored by our rich industry experience, we are occupied with offering Sheet Metal Stampings to our important customers. It is planned to change over level metal sheets into explicit shapes. This item levels increment, settling on exactness metal stepping a decent decision for high-volume creation of complex parts. All the provided items are watched out for the distinctive quality limits prior to passing on them from our premises. Offered Sheet Metal Stampings is conveyed by us at a sensible value rate.

Specification

Brand | Sunny |

Usage/Application | Industrial |

Tolerance | 0.01-0.02 mm |

Thickness | 0.5-12 mm |

Surface Treatment | Polished |

Packaging Type | Box |

Material | Stainless Steel |

Features | Optimum Strength, Convenient to Use, Resistant to Rust |

Precision and Versatility Combined

Sheet metal stampings are manufactured using precise technologies such as laser, CNC, and die cutting, offering unmatched adaptability for custom shapes and dimensions. Our capability extends to both high-volume and low-volume production, with a focus on consistent quality, dimensional accuracy, and application-specific configurations. Combined with deburred, safe edges, our solutions are ideal for complex industrial requirements.

Quality Materials and Surface Options

We utilize a broad selection of base metals, including mild steel, stainless steel, aluminium, brass, and copper. Each stamping can be produced according to material hardness specifications. Our surface finishes include electroplating, powder coating, anodizing, and painting. Custom color options and corrosion-resistant coatings ensure your parts are both durable and visually appealing.

Applications Across Key Industries

Our sheet metal stampings are designed for use in automotive chassis, electrical enclosures, construction brackets, panel covers, and more. They are suitable for a variety of assemblies and components required in industrial, electrical, and automotive sectors. Customized mounts, shapes, and packing solutions cater to unique project and export needs.

FAQs of Sheet Metal Stampings:

Q: How are the sheet metal stampings produced and finished?

A: Sheet metal stampings are created using laser, CNC, or die cutting methods, followed by punching, bending, and forming processes. Edges are deburred to eliminate sharpness, and parts can be surface treated with electroplating, powder coating, anodizing, or painting for enhanced appearance and corrosion resistance.Q: What materials and thicknesses are available for these stampings?

A: We manufacture stampings from mild steel, stainless steel, brass, copper, and aluminium, with thicknesses ranging from 0.5 mm to 5 mm. The final hardness aligns with the specific material requirements.Q: When can I expect delivery after placing an order?

A: Lead time is typically 2-4 weeks after your order is confirmed, depending on order volume, customization, and finishing requests.Q: Where can these sheet metal stampings be used?

A: Our stampings are widely utilized in automotive, electrical, industrial, and construction applications, including chassis, brackets, covers, panels, and custom parts for assemblies.Q: What is the minimum order quantity (MOQ)?

A: The minimum order quantity for sheet metal stampings is 500 pieces, which suits both small and large-scale production needs.Q: How can I request corrosion resistance or specific surface treatments?

A: Corrosion-resistant coatings such as zinc plating, nickel plating, or powder coating can be provided on request. Please specify your surface treatment needs while placing the order.Q: What are the benefits of choosing your sheet metal stampings?

A: Our products offer precise tolerances, custom dimensions, smooth and safe edges, multiple finish options, and packaging tailored to export requirements, ensuring high performance and reliability for various industry applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sheet Metal Components Category

Progressive Tool Components

Price 5 INR / Piece

Minimum Order Quantity : 500 Pieces

Shape : Rectangular, Custom Shaped

Material : Other, Tool Steel

Usage : Stamping, Punching, Cutting

Dimension (L*W*H) : Customized

Press Parts

Price 5 INR / Piece

Minimum Order Quantity : 500 Pieces

Shape : Rectangular / Circular / Custom

Material : Other, Mild Steel / Stainless Steel

Usage : Industrial Machinery Support

Dimension (L*W*H) : Customizable as per requirement

Automotive Brackets

Price 5 INR / Piece

Minimum Order Quantity : 500 Pieces

Shape : LShaped

Material : Other, Mild Steel (MS)

Usage : Mounting & Support

Dimension (L*W*H) : 120mm x 80mm x 40mm

Precision Pressed Components

Price 5 INR / Piece

Minimum Order Quantity : 500 Pieces

Shape : Rectangular, Custom shapes

Material : Other, Cold rolled steel, Stainless steel

Usage : Mechanical assembly, Electrical enclosures

Dimension (L*W*H) : Custom as per requirement

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS