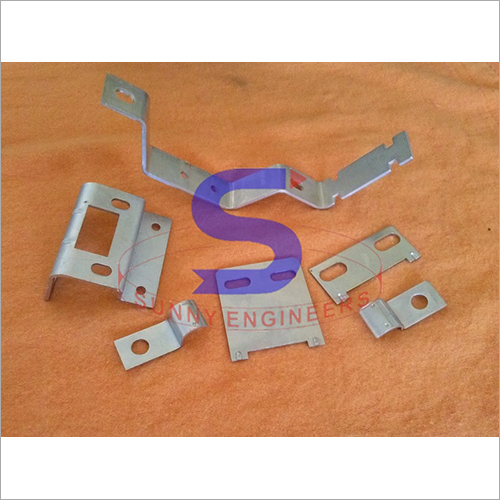

Tubular Pressed Parts

Price 5 INR/ Piece

Tubular Pressed Parts Specification

- Application

- Automotive, Electrical, Machinery, Structural Components

- Dimension (L*W*H)

- As per customer requirement

- Usage

- Industrial Applications

- Components

- Tubular Pressed Parts

- Surface Finishing

- Smooth

- Coating Type

- Galvanized or Painted

- Hole Size

- Customizable as per Drawing

- Mount Type

- Through Hole or Threaded as per design

- Weight

- Varies as per part size

- Shape

- Tubular Cylindrical

- Material

- Mild Steel

- Tolerance

- 0.05 mm

- Thickness

- 1 mm to 3 mm

- Capacity

- Customizable

- Surface Treatment

- Zinc Plated

- Making Process

- Pressed and Welded

Tubular Pressed Parts Trade Information

- Minimum Order Quantity

- 500 Pieces

- Supply Ability

- 300000 Pieces Per Month

- Delivery Time

- 30 Days

About Tubular Pressed Parts

When it comes to buying the qualitative various kinds of items, our firm is the first choice of our patrons. Here we are providing Tru Flex Component that is formulated by using high quality required components with the help of advanced technology. This Tru Flex Component is a maker and advertiser of adaptable metal hose items utilized for patented parts for on-street and rough terrain EPA consistent fumes frameworks. Also, it is used as metal hose for general mechanical applications.

Superior Durability and Corrosion Resistance

These tubular pressed parts undergo zinc plating, offering corrosion resistance for up to 800 hours in salt spray tests (ASTM B117). Their robust design endures temperatures from -40C to +180C, making them reliable in demanding environments. Available hardness values (HRC 20-55) and impact strength testing further enhance longevity for critical industrial uses.

Tailored Dimensions and Finishing

Each component can be fully customized, from the external dimensions and edge profiles to finishing options and markings. With a tight tolerance of 0.05 mm and selectable thickness between 1 mm and 3 mm, clients can order parts built precisely for their application. Additional options include surface treatments such as galvanizing or painting, ensuring optimal performance and protection.

Streamlined Manufacturing and Support

Produced in India, our pressed and welded tubular components utilize advanced manufacturing techniques and are backed by experienced suppliers. We support design collaboration through 3D CAD file exchanges and offer full OEM and export services. Packaging options include shrink wrap, carton boxes, and palletization to meet client logistics needs.

FAQs of Tubular Pressed Parts:

Q: How are the tubular pressed parts manufactured and finished?

A: The tubular pressed parts are produced using pressed and welded mild steel processes. They undergo surface treatment by zinc plating, which can be optioned as galvanized or painted finishes. This approach ensures durable, smooth surfaces with high resistance to corrosion.Q: What customization options are available for these components?

A: Clients can fully customize dimensions (L*W*H), edge profiles (rounded, chamfered, or straight cut), hole sizes, mounting types (through hole or threaded), surface finishing, markings, and packaging. Color options include silver, black, or custom finishes, with OEM and design (3D CAD) support provided.Q: When can I expect delivery after placing an order?

A: Standard lead time is 2 to 4 weeks, depending on order quantity and customization requirements. Efficient packaging (shrink wrap, carton box, pallet) ensures safe and organized shipping.Q: Where are these tubular pressed parts manufactured and exported from?

A: All components are manufactured by certified suppliers in India and exported globally. The manufacturing facilities comply with ISO 9001:2015 and RoHS standards, ensuring quality and environmental responsibility.Q: What are the primary industrial applications for these parts?

A: These tubular pressed parts are engineered for use in automotive, electrical, machinery, and structural component industries. Their customizable features and high durability make them suitable for a range of heavy-duty and precision applications.Q: How do these parts benefit my operation or project?

A: With customizable manufacturing, proven corrosion and temperature resistance, tight tolerances, and robust mechanical strength, these components greatly enhance system reliability, reduce maintenance needs, and ensure compatibility with precise project specifications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sheet Metal Components Category

Tubular Pressed Parts

Price 5 INR / Piece

Minimum Order Quantity : 500 Pieces

Dimension (L*W*H) : Customizable as per requirements

Application : Tubular Frame Joints, Mounting, Machine Fittings

Material : Other, Mild Steel, Stainless Steel, Aluminum

Surface Finishing : Smooth, Matte, Glossy

Automotive Brackets

Price 5 INR / Piece

Minimum Order Quantity : 500 Pieces

Dimension (L*W*H) : 120mm x 60mm x 30mm

Application : Passenger Cars, SUVs, Commercial Vehicles

Material : Other, Cold Rolled Steel

Surface Finishing : Matte Black

Customized Sheet Metal Brackets

Price 5 INR / Piece

Minimum Order Quantity : 500 Pieces

Dimension (L*W*H) : Custom as per drawing / requirement

Application : Industrial Machinery, Electrical Panels, Architecture

Material : Other, Mild Steel, Stainless Steel, Aluminum

Surface Finishing : Smooth, Polished

Sheet Metal Pressed Component

Price 5 INR / Piece

Minimum Order Quantity : 500 Pieces

Dimension (L*W*H) : As per customer drawing or requirement

Application : Automobile, Electrical, Electronics, Construction

Material : Other, Mild Steel, Stainless Steel, Brass, Aluminum

Surface Finishing : Smooth, Burr free, Corrosion resistant

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS